What to Do if Your Boiler Condensate Pipework Freezes

When temperatures drop below zero, one of the most common reasons a boiler stops working is a frozen condensate pipe. If your boiler is showing a fault code, isn’t firing, or keeps going into lockout during icy weather, the condensate pipe is usually the culprit.

The good news is that this is a very fixable issue — and in many cases, you can safely defrost the pipe yourself. In this guide, we explain what the condensate pipe does, how to spot a frozen pipe, safe ways to thaw it, how to prevent it freezing again, and when to call a heating engineer.

What Is a Condensate Pipe and Why Does It Freeze?

Modern condensing boilers remove heat from exhaust gases, which produces a small amount of acidic water called condensate. This condensate must be drained safely, usually through a plastic pipe that runs outside the property.

During very cold weather, this external pipe can freeze — especially if it is:

- too small (less than 32mm diameter)

- poorly insulated

- exposed to cold winds

- has long horizontal runs

- located in a shaded or north-facing area

When the pipe freezes, condensate can’t drain away, causing the boiler to lock out as a safety precaution.

Signs Your Condensate Pipe Has Frozen

If your boiler isn’t working in freezing weather, a frozen condensate pipe is the most likely cause. Common symptoms include:

- Boiler displaying a fault code (often relating to drainage or ignition)

- A gurgling or bubbling sound inside the boiler

- Boiler repeatedly attempts to fire but fails

- No heating or hot water

- Water backing up inside the boiler

- Ice buildup on the external pipe

If the external pipe feels solid or you can visibly see ice, you’ve found the issue.

How to Safely Thaw a Frozen Condensate Pipe

Thawing the pipe is usually simple and takes only a few minutes. Follow the steps below.

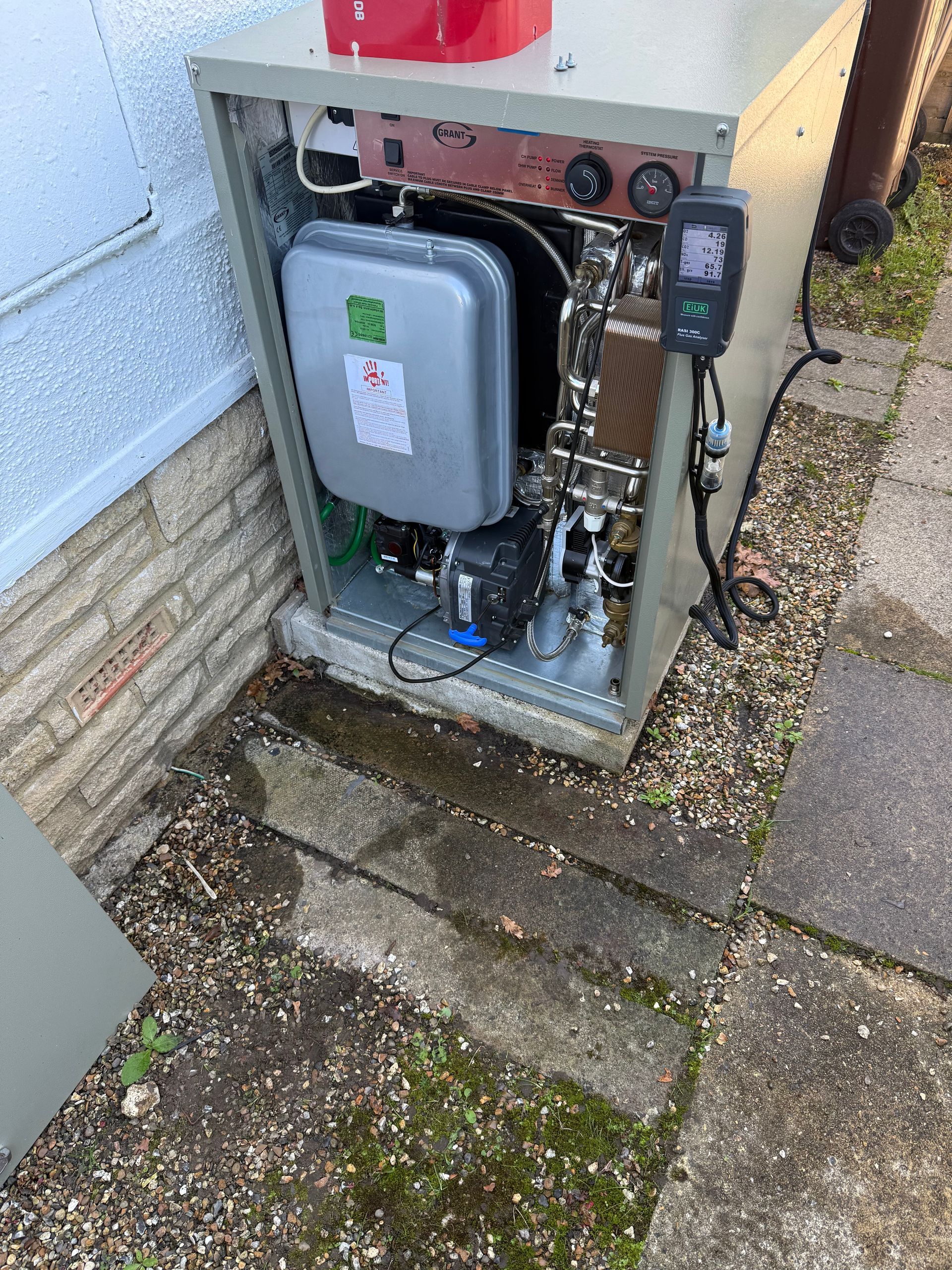

1. Locate the External Condensate Pipe

This is usually a white or grey plastic pipe running outside the property from the boiler to a drain or soakaway. The frozen section is typically the most exposed part.

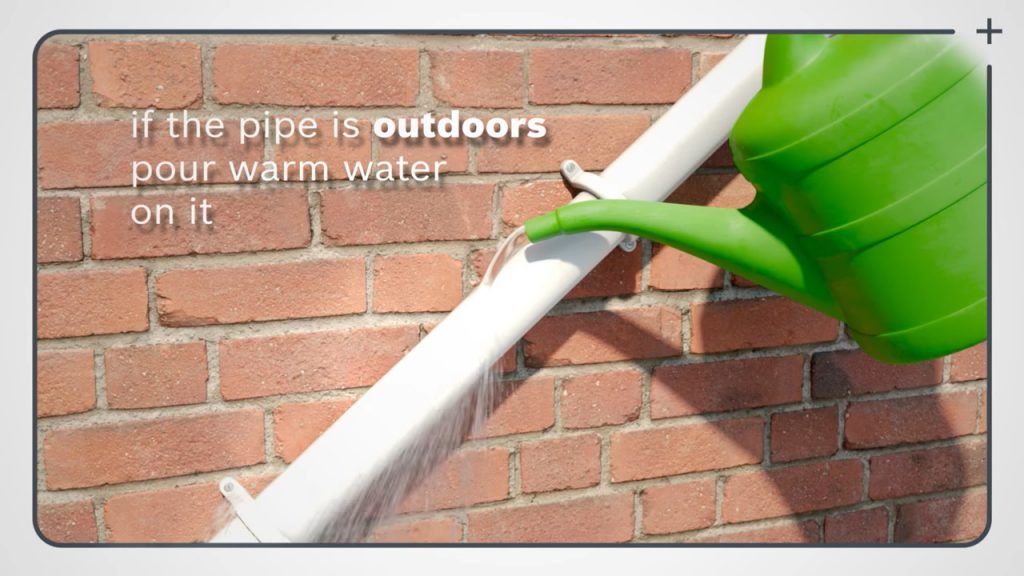

2. Use Warm Water (Not Boiling Water)

Pour warm (not boiling) water over the pipe, starting from the bottom and moving upwards.

Boiling water can crack the plastic, so avoid using kettles straight off the boil.

Ways to apply warm water safely:

- Use a jug of warm water

- Apply a warm cloth or hot-water bottle over the frozen area

- Use repeated gentle pours rather than one large splash

3. Reset the Boiler

Once the pipe has thawed, return to your boiler and press the reset button. It should restart normally.

4. Check the Pipe for Further Ice

Sometimes multiple sections freeze. Make sure the entire exposed length is thawed.

If the boiler still does not fire, the pipe may be blocked internally, the trap may be frozen, or there may be a more complex issue — in that case, call a Gas Safe engineer.

Temporary Measures to Get You Back Up and Running

In extremely cold conditions where you cannot fully thaw the pipe, a temporary fix may help:

1. Bring the Pipe Indoors (If Safe)

If the pipe has been poorly installed externally, it may be possible to temporarily run it internally into a sink or waste point — but only do this under guidance.

2. Leave Heating Running Continuously

Keeping the heating on low rather than letting the system cool overnight prevents condensate from freezing again.

3. Use an External Heat Source Carefully

A hairdryer on a low setting can gently warm stubborn frozen areas.

Never use naked flames, blowtorches or anything unsafe.

How to Prevent Your Condensate Pipe Freezing Again

Prevention is the best solution. A heating engineer can upgrade or modify your pipework to ensure freezing becomes far less likely.

1. Increase the Pipe Size to 32mm or 40mm

A wider pipe is less likely to freeze and allows condensate to drain faster.

2. Add High-Quality Insulation

UV-resistant outdoor insulation sleeves protect the pipe from cold winds.

3. Shorten External Pipe Runs

The less pipe exposed outdoors, the better the protection against freezing.

4. Install Trace Heating (Heater Cable)

This low-energy, self-regulating cable warms the pipe automatically during freezing temperatures.

5. Improve the Fall/Gradient of the Pipe

A steeper angle helps condensate drain quickly, reducing the risk of standing water freezing.

6. Regular Boiler Servicing

Annual servicing checks the trap, condensate pathways and external pipework to ensure everything flows freely.

When to Call a Heating Engineer?

While most frozen condensate pipes are simple to fix, you should call a professional if:

- The pipe continues to freeze frequently

- The pipe is damaged or cracked

- You don’t feel confident thawing it

- The boiler still does not restart after thawing

- Water is leaking from joints or inside the property

A Gas Safe engineer can inspect the installation, advise on long-term prevention and ensure your boiler operates safely.

Stay Warm and Avoid Boiler Breakdowns This Winter

A frozen condensate pipe is one of winter’s most frustrating but easily avoidable boiler issues. By understanding the warning signs, knowing how to thaw the pipe safely, and taking preventive steps, you can keep your heating running smoothly—even in severe weather.

If your condensate pipe keeps freezing or your boiler won’t reset after thawing, our expert engineers are here to help. We can upgrade your pipework, install insulation, fit trace heating and ensure your boiler is winter-ready.